Why are Aluminium Extrusions Used in Construction?

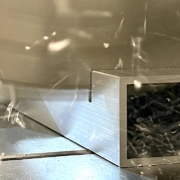

Aluminium Extrusions in Construction

As specialists in the design, fabrication and finish of aluminium extrusions, the Salesmade Ltd team works with the same metal every day.

Our products are used in the construction of buildings, vehicles, interior fittings and cabling systems. This article explains why aluminium is an ideal material for these applications and why don’t we extrude other metals.

The method of extracting pure aluminium was not achieved until 1827 and the metal was not commercially produced until 1886, so it is relatively new material. Over the last 130 years, its desirable properties have ensured that it is central to the development of many items. What makes aluminium desirable?

Properties of Aluminium

Aluminium is a low-density metal, so it is lightweight, however, it has a high strength to weight ratio. The strength can be further increased by mixing aluminium with other metals including copper, magnesium, silicon and manganese to form an alloy.

Aluminium is malleable and ductile, so it can be stretched into complex forms whilst retaining its strength. This means that lengths of aluminium extrusions hold their shape and don’t sag or distort under their own weight.

Aluminium is naturally resistant to corrosion and isn’t damaged by UV light and other external pressures. These properties can be further enhanced by anodising or powder-coating aluminium, but these finishes are often used for aesthetic purposes. An anodised finish thickens the natural oxide layer of the metal and dyes can be added to provide colour. Powder-coating is a sprayed finish that delivers added protection and consistent colour.

Aluminium has high thermal and electrical conductivity. This means it can increase energy efficiency when used in air conditioning, electronics and cabling.

Aluminium is not magnetic and non-toxic. These properties are vital in many applications, including the use of aluminium foil as food packaging.

Is Aluminium a Sustainable Metal?

With a growing interest in environmental impact, more companies are looking for sustainable materials. In many cases, evidencing supply chain sustainability is a prerequisite of commissioning, planning approval or funding. So, how does aluminium fair?

Much of the global supply of aluminium is extracted in Australia, China and Brazil. We know that raw materials are finite, so optimising use is essential for sustainability.

Fortunately, aluminium can be recycled and reused an infinite number of times. It uses 95% less energy to produce aluminium from recycled material than from raw material and all its properties are retained through the process. This makes it a permanently available resource.

Eddy Current Separators are installed in most UK recycling centres. These channel aluminium frames, marine parts, drinks cans and more away from other materials. The process of turning them back into usable aluminium can then take place. This is a great example of the circular economy in action.

Why only Aluminium Extrusions?

Other metals can be extruded, but not with the same ease of production as aluminium and alu-alloys. This malleable metal passes through the die to form the desired shape with tight tolerances. The shape is held, offering a consistent cross-section even when the extrusion is cut for product assembly.

With informed profile design, aluminium components can be extruded to incorporate features that simplify assembly. These include interlocking details, fixings and channels which reduce the need for machining at later stages of production. This is more challenging to achieve with alternative metals.

In summary, we specialise in aluminium extrusion design, fabrication and finishing because this metal is strong, lightweight, recyclable and offers the flexibility of design.

With knowledge of the material and processes, the Salesmade Ltd team provide invaluable support with the development of prototypes, manufactured components and fully assembled parts. Contact us on 01296 431292 or sales@salesmade.co.uk to discuss your requirements.