Automotive Product Design & Development

Automotive Product Design & Development

THE CLIENT:

A leading British car manufacturer

THE BRIEF:

To create a replacement part for a component that had proved faulty

THE CHALLENGE:

A new 4 x 4 vehicle was launched in the late 1970’S – early 1980’s, but a decade later, the rear windscreen was proving an issue. In the original design, the manufacturing technology, materials and cost factors had meant that steel pressings were used. On all-terrain vehicles, parts are exposed to the elements and put through their paces. Over time, the windscreens were proving susceptible to rust, which looked unsightly, allowed water into the vehicle and put the rear windscreen at risk of falling out.

The aftermarket parts supplier wanted a corrosion-resistant replacement. They approached Salesmade Ltd to see if we could come up with a viable solution.

OUR SOLUTION:

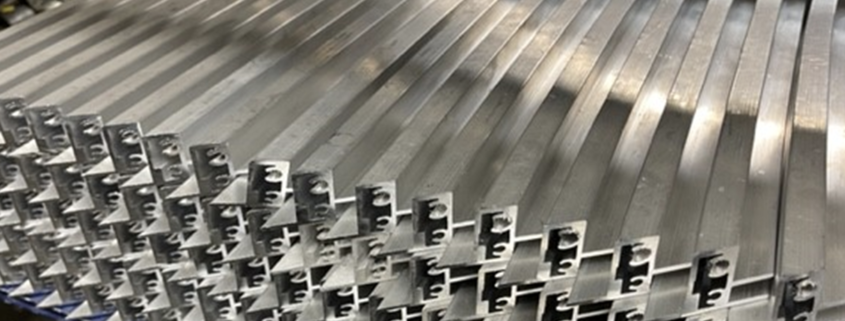

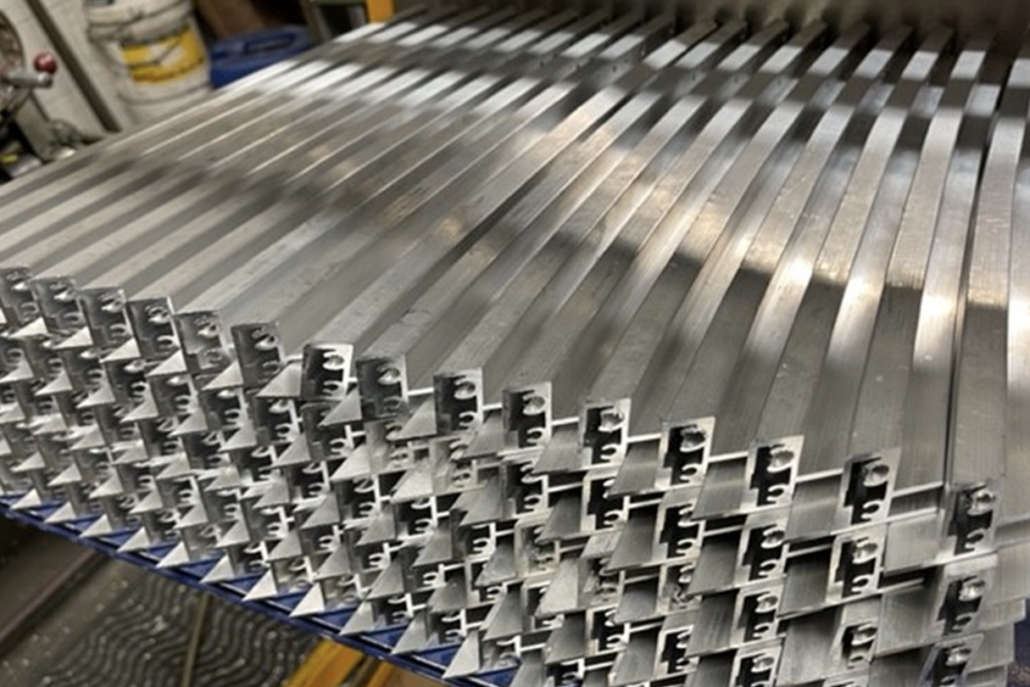

As specialists in aluminium extrusions and fabrication, we were able to work with their specifications to draw up a cost-effective replacement. We manufactured the design, providing a perfect fit that fulfilled the quality expectations of the vehicle manufacturer. Our solution proved stronger, lighter and more suitable for the environments in which 4 x 4 vehicles are used.

THE OUTCOME:

We got the order and the Salesmade Ltd team continue to manufacture these aluminium windscreens to this day. That’s a testament to the design of the replacement product and the aluminium extrusion process. The vehicle model is now a widely sought-after classic, so our customer ships the parts worldwide, for use in restoration projects.