What Do You Want to Know About Aluminium?

We’re keen to educate people about aluminium as this metal has many desirable qualities and untapped potential. It is an abundant metal which is infinitely recyclable. So, in a world where we need to champion resource efficiency and circular thinking, aluminium fits the bill.

At the moment, we are training our first modern apprentice. He’s gaining knowledge of processes, machine operation, fabrication and applications from every member of the team. With his questions in mind, we thought you might also be interested to know more. Maybe this insight can inspire your career direction or support the development of an innovative prototype.

What Are the Desirable Qualities of Aluminium?

Aluminium has many desirable qualities which include the fact that:

- It has intrinsic strength, yet is a lightweight metal

- It is sufficiently versatile to be formed into almost any shape, yet holds its form

- It oxidises naturally, creating a barrier that prevents rust

- It is a long-lasting and low-maintenance material

- It is a sustainable and 100% recyclable material

- It can be produced as a thin foil, through to thick and robust forms

The properties of pure aluminium are further enhanced by combining it with other metals, including magnesium, silicon, zinc, and copper to form an aluminium alloy. This can increase corrosion resistance, thermal or electric conductivity and strength. It also affects the finished look of the metal. If you have a specific application or finish in mind, ask us to recommend a suitable aluminium alloy.

What Industries Use Aluminium?

You’ll find aluminium is used in most industries. It is used in the construction of buildings, machinery aircraft and motor vehicles. Equally, extruded aluminium frames are a practical choice for windows, solar panels, electrical lighting ducts, sports equipment, furniture and interior fittings. And, if you take a look, you may have aluminium utensils, foil and food cans in your kitchen cupboards.

What is an Aluminium Extrusion?

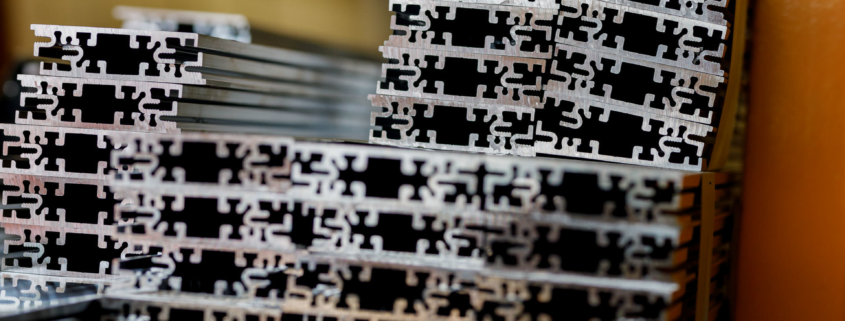

Aluminium extrusions are suitable for applications requiring lengths with a uniform cross-section. In the process, a custom die is created and heated aluminium bars (known as billets) are pushed through. As the metal cools, it retains the shape of the die.

To achieve a smooth flow of metal through the die, uniformity and symmetry are ideal. We advise against sharp corners and deep, narrow sections. Use our expertise in aluminium extrusions to reduce potential issues and design in elements such as bolt slots, hinges and screw grooves that reduce post-extrusion machining.

We are specialists in the design, fabrication and finish of aluminium extrusions. To ensure a precision finish, we work to BS EN 755-9. This is the industry standard for extruded aluminium profiles. This covers the width, depth, wall thickness and the straightness of extruded lengths. We cut, fabricate, finish, and assemble these lengths to form a wide range of products and parts.

What are the Finish Options for Aluminium?

Mill finished is the term to describe an aluminium extrusion with no surface treatment. The metal naturally oxidises to form a protective outer layer with a matt appearance.

Other finish options are:

- Anodised – an electrochemical process that produces a thicker oxide layer that gives the aluminium enhanced strength and structure.

- Powder Coated – for added corrosion resistance and a RAL colour match.

- Polished – some aluminium alloys can be buffed and polished to create a shiny finish.

Can you Paint Aluminium?

Yes, metal paints will adhere to aluminium. However, for a smooth, resistant and low-maintenance colour finish, we recommend powder coating. We have the equipment, space and skilled team to undertake anodising, powder coating and polishing of aluminium on-site.

Why is Aluminium Considered a Sustainable Choice?

The main reason that aluminium is a sustainable material is that it’s infinitely recyclable. Every tin in your cupboard can go in the recycling bin when you’ve consumed the contents. Then it can be made into new cans. Equally, our offcuts and parts can be fully recycled. This minimises the extraction of new metals, which is far more carbon-intensive than reusing aluminium.

For companies in the construction industry, there is even a Closed Loop Recycling Scheme. This membership scheme provides financial incentives to firms that collect waste aluminium. The metal alloys are separated to increase recyclability and reuse.

At this point, we want to mention our local litter picking volunteers, Aylesbury Wombles. They’ve collected nearly half a million discarded aluminium drink cans from the streets of our town since September 2020. These have all been taken to ASM Metal Recycling, turning waste into valuable material. What a fantastic initiative!

How Can I Find Out More About Aluminium?

If you have specific questions about aluminium for your products, get in touch with our team on 01296 431292 or sales@salemade.co.uk.

For a more general overview, there is a free online course which has recently been launched by European Aluminium. ‘Aluminium Unveiled: A Comprehensive Journey from History to Sustainability’. Does that appeal?